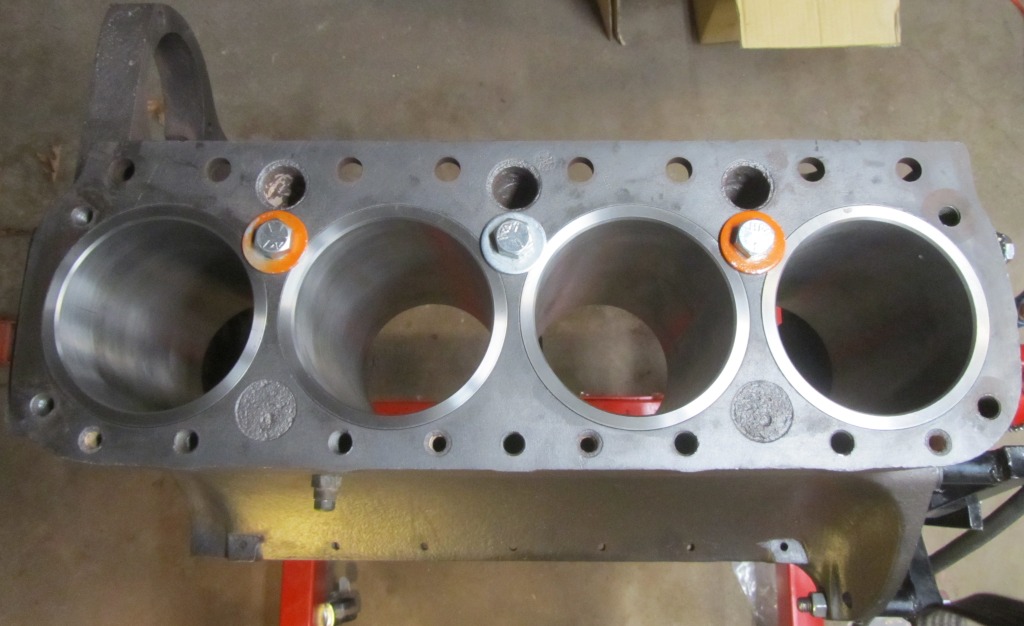

The block is back from cleaning and align boring so I shouldn't need shims.

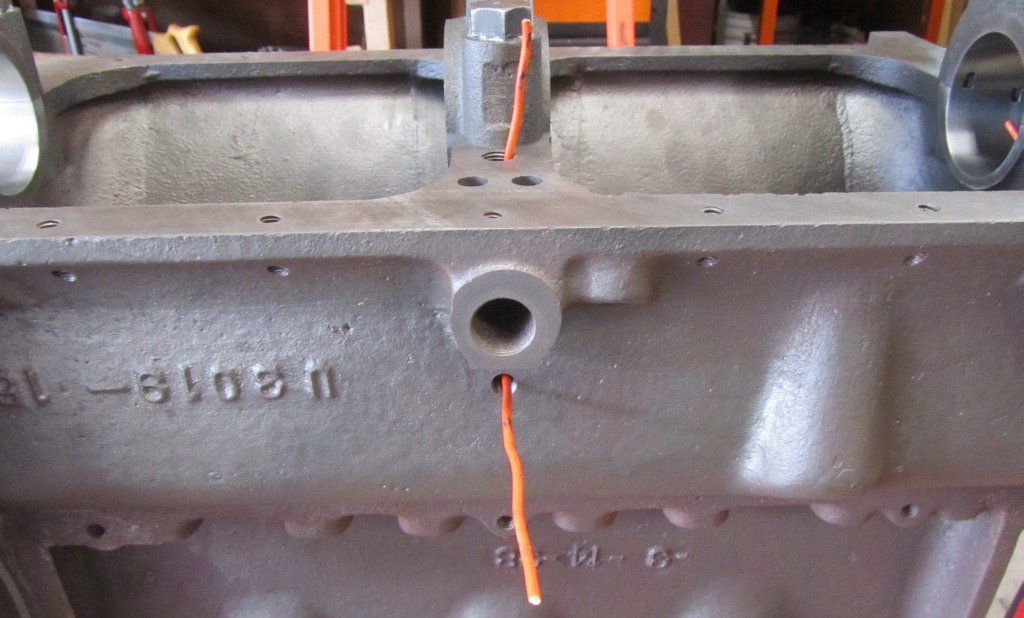

Using some appropriately

colored wires I wanted to follow the paths the pressurized oil takes.

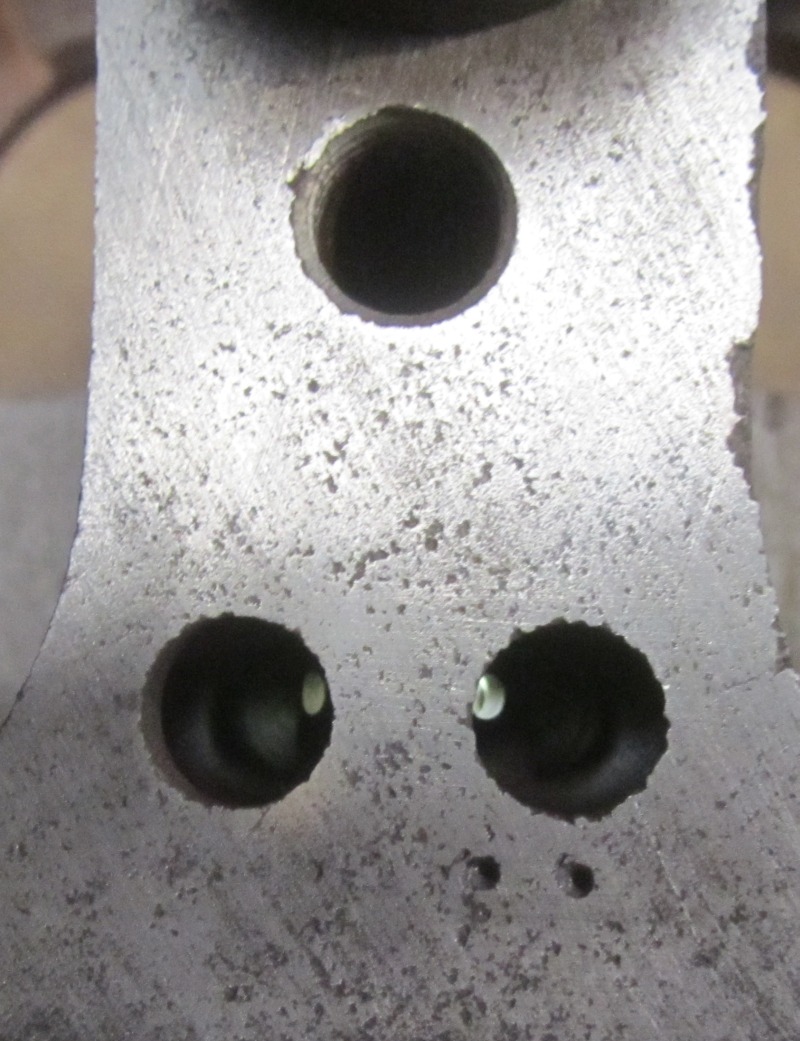

And with a light shining through the oil relief valve plunger

The external line is drilled to get presurized oil

The center main bearing and cam bearing get a direct feed

The camshaft is hollow and feeds the front and rear main bearings.

And the crankshaft main journals are drilled to feed the neighboring rod journals.

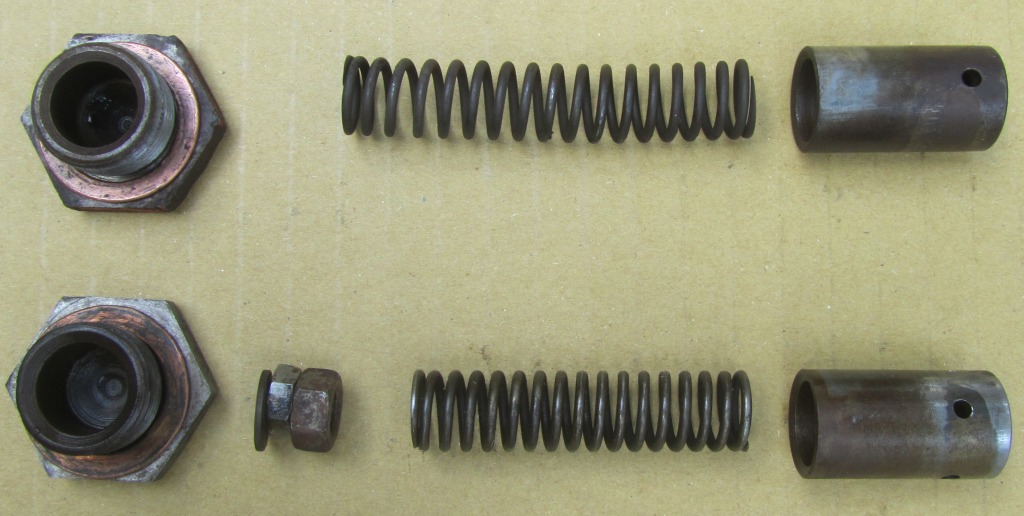

Since I took apart the 1934 motor S/N W312 as well as this 38 WF engine

I was able to see a couple of

methods of trying to increase oil pressure.

I needed to find out whether one spring had been stretched or the other was compressed.

I took one out

of a 1939 parts engine and see it identical to the shorter one.

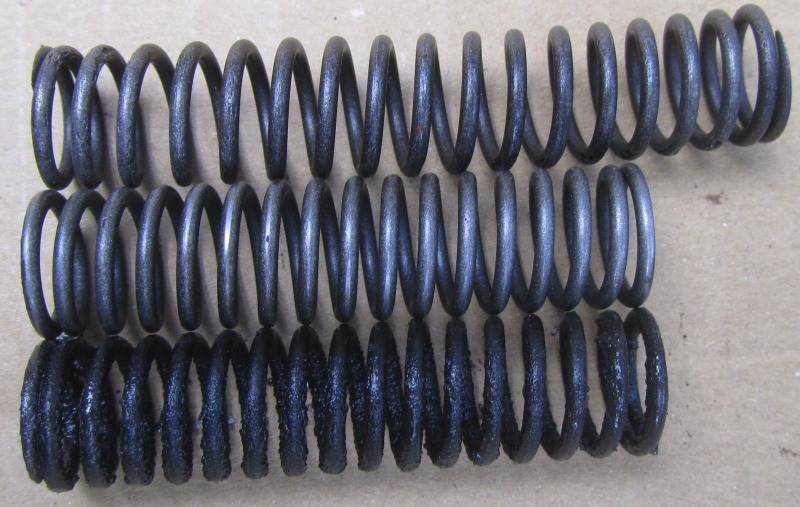

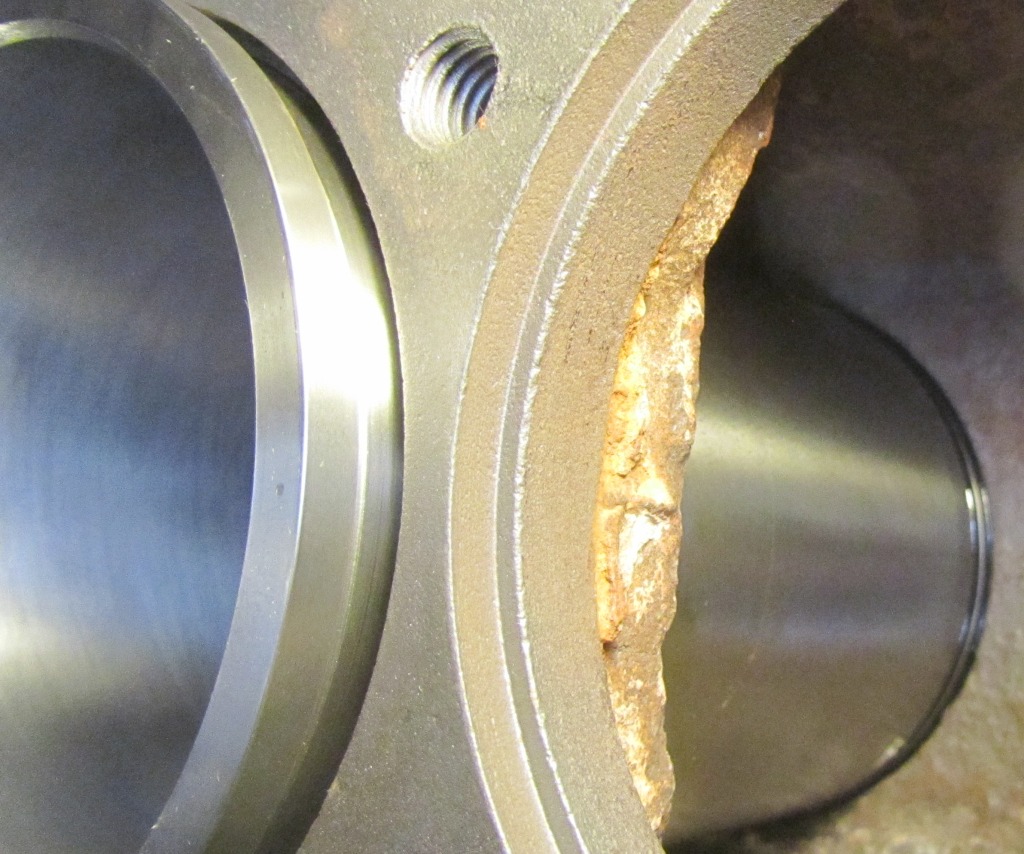

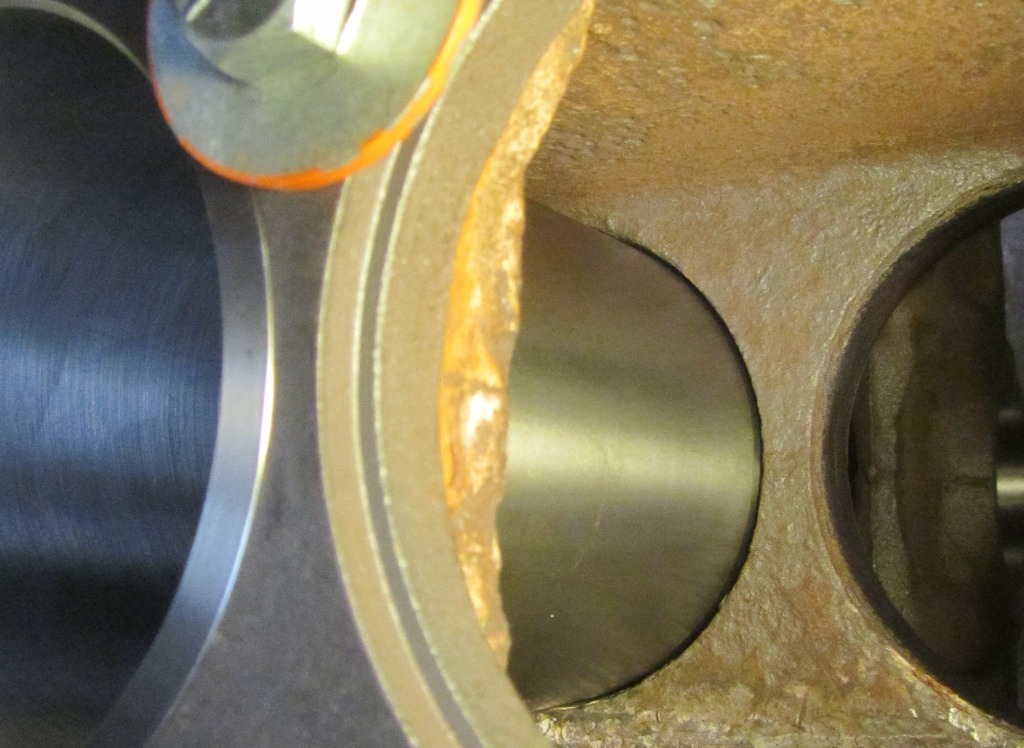

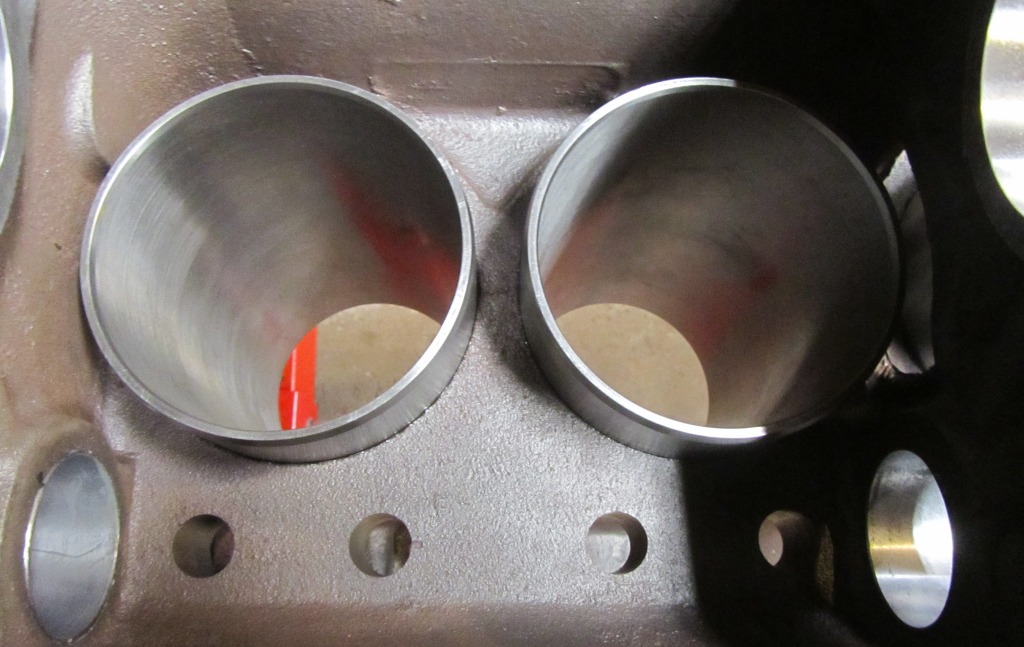

I used a flapper wheel to shine up the sleeve O-ring surfaces.

It certainly looks nicer than when the old ones came out.

All four in and the standout on all are good.

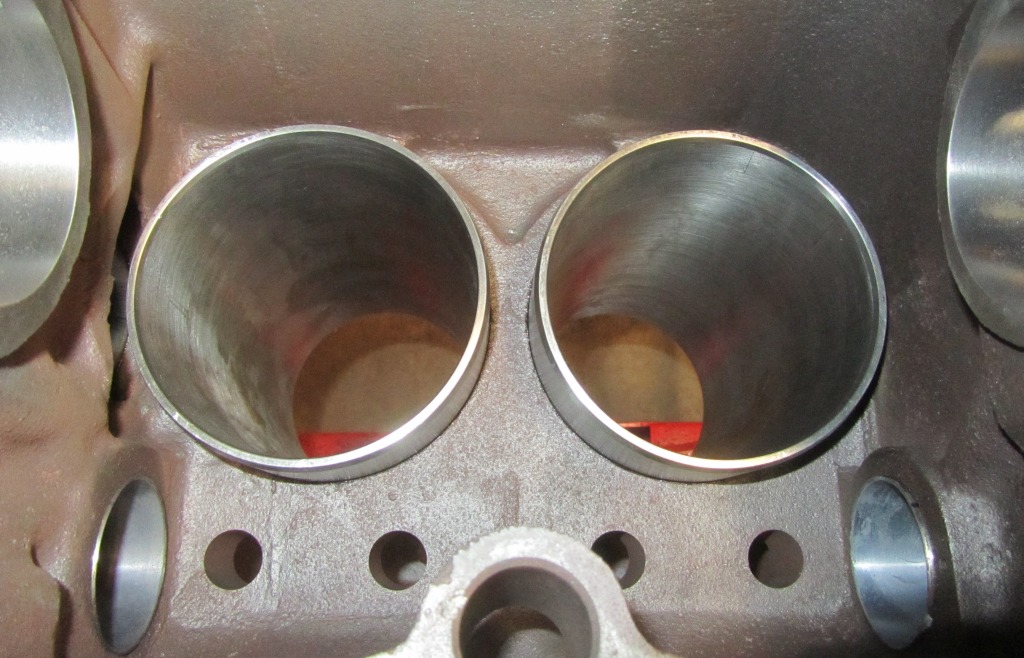

From the bottom we can see the new cam bearings too.

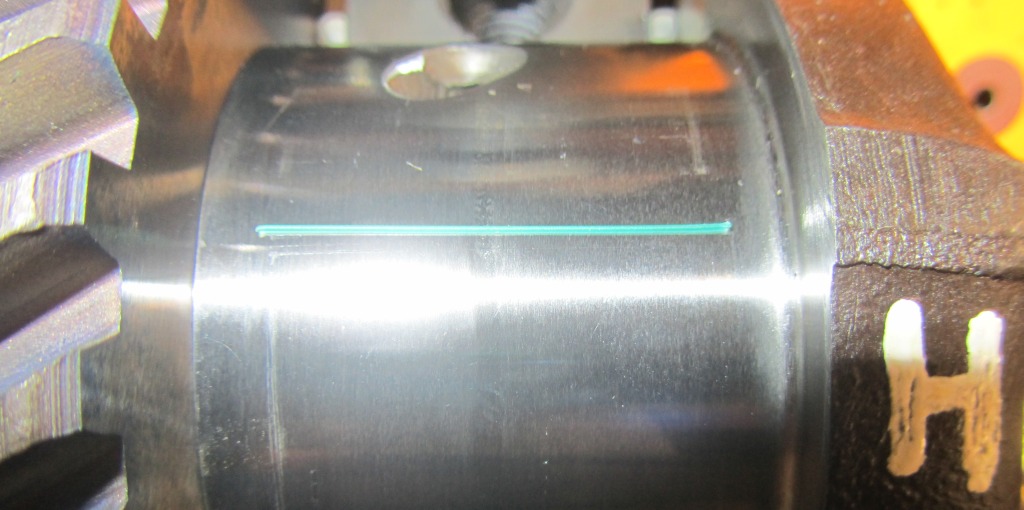

It is ready for the crankshaft I checked them with plastigage for peace of mind.

I didn't get it lined up perfectly for the photo but they are each a bit over .002 and less than .003 which

is OK.